A supply chain is a crucial aspect of any business, as it involves the entire process of creating and delivering products or services to the end consumer. It is a complex network that involves various entities, resources, and processes working together to ensure the smooth flow of goods from suppliers to customers. In this article, we will explore what best describes what a supply chain is, its key elements, types, functions, and more.

What Best Describes What a Supply Chain is Everfi

Everfi is an online platform that provides educational courses on various topics, including supply chain management. According to Everfi, a supply chain is “the network of organizations, people, activities, information, and resources involved in moving a product or service from supplier to customer.” This definition highlights the interconnectedness and collaboration between different entities in a supply chain.

Understanding the Key Elements of a Supply Chain

To better understand what a supply chain is, let’s break down its core components:

- Suppliers: These are entities that provide raw materials, components, or services necessary for the production of a product or service.

- Manufacturers: They transform these raw materials into finished products.

- Distributors: These entities store and distribute products to retailers or directly to consumers.

- Retailers: They sell products directly to consumers.

- Customers: The end-users who purchase and consume the products or services.

These elements work together to ensure the efficient and timely delivery of products or services to the end consumer. Any disruption or inefficiency in one element can affect the entire supply chain.

Exploring the Types of Supply Chains

Supply chains can vary based on the industry, product, and business model. Some common types include:

- Linear supply chain: This is a simple, sequential process where materials flow from suppliers to manufacturers to distributors and finally to consumers.

- Divergent supply chain: In this type of supply chain, a single product is used to create multiple output products. For example, a dairy farm may produce milk, cheese, and yogurt from the same source.

- Convergent supply chain: Here, multiple input products are used to create a single output product. An example of this is a bakery that uses flour, sugar, and eggs to make different types of bread.

- Hybrid supply chain: This is a combination of linear, divergent, and convergent supply chains. It is often seen in complex industries where multiple products are produced and distributed through various channels.

Understanding the different types of supply chains can help businesses identify which model best suits their needs and goals.

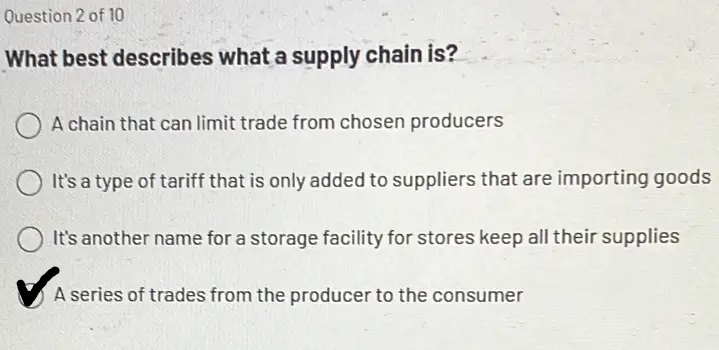

Which Statement Best Describes a Supply Chain

There are many ways to describe a supply chain, but one statement that accurately captures its essence is “a network of interconnected entities working together to deliver products or services to the end consumer.” This statement emphasizes the collaboration and interdependence between suppliers, manufacturers, distributors, retailers, and customers in a supply chain.

What is Supply Chain Quizlet

Quizlet is an online learning platform that provides study tools for students and educators. According to Quizlet, a supply chain is “the sequence of processes involved in the production and distribution of a commodity.” This definition highlights the sequential nature of a supply chain, where each step is crucial in ensuring the final product reaches the end consumer.

What is the Best Definition of Supply Chain Management

Supply chain management (SCM) is the process of overseeing and managing all activities involved in the creation and delivery of products or services. The best definition of SCM would be “the coordination and integration of all supply chain activities, from sourcing raw materials to delivering the final product to the end consumer.” This definition emphasizes the importance of effective communication, collaboration, and optimization of resources within a supply chain.

Functions of a Supply Chain

The main functions of a supply chain are:

- Planning: This involves identifying demand and determining the necessary resources and processes to meet that demand.

- Sourcing: It involves selecting and managing suppliers to ensure a steady supply of raw materials or components.

- Production: This function includes transforming raw materials into finished products through various manufacturing processes.

- Inventory management: It involves monitoring and controlling the levels of inventory to ensure efficient production and timely delivery.

- Logistics: This function focuses on the transportation, storage, and distribution of products to their final destination.

- Customer service: Ensuring customer satisfaction is a crucial function of a supply chain. This includes handling inquiries, complaints, and returns.

Challenges in Supply Chain Management

Managing a supply chain can be a complex and challenging task, especially in today’s globalized and fast-paced business environment. Some common challenges faced by supply chain managers include:

- Demand forecasting: Accurately predicting demand is crucial for effective planning and inventory management. However, it can be challenging due to factors such as changing consumer behavior and market trends.

- Supply chain visibility: With multiple entities involved in a supply chain, it can be challenging to have complete visibility and control over all processes. This can lead to delays, disruptions, and inefficiencies.

- Supply chain risk management: Disruptions such as natural disasters, supplier bankruptcy, or political instability can significantly impact a supply chain. Managing these risks is essential to ensure continuity and minimize losses.

- Cost management: Balancing costs while maintaining quality and efficiency is a constant challenge in supply chain management. Rising costs of raw materials, labor, and transportation can affect the overall profitability of a supply chain.

- Technology integration: As technology continues to advance, supply chain managers must keep up with the latest tools and systems to optimize processes and stay competitive.

The Role of Technology in Supply Chain Management

Technology has played a significant role in transforming supply chain management in recent years. With the rise of e-commerce and global trade, businesses are increasingly relying on technology to streamline processes, improve efficiency, and enhance customer experience. Some key technologies used in supply chain management include:

- Enterprise Resource Planning (ERP) systems: These software solutions integrate various business functions, such as finance, inventory, and production, into one system. This allows for better coordination and communication between different departments.

- Supply Chain Management (SCM) software: These tools help manage and optimize supply chain processes, from planning and sourcing to logistics and customer service.

- Internet of Things (IoT): IoT devices can track and monitor products throughout the supply chain, providing real-time data on location, temperature, and other important metrics.

- Artificial Intelligence (AI): AI-powered systems can analyze vast amounts of data and provide insights to improve decision-making and forecasting in supply chain management.

- Blockchain: This technology enables secure and transparent tracking of products and transactions, making it useful in supply chain management.

Conclusion

In conclusion, a supply chain is a complex network of entities, resources, and processes working together to deliver products or services to the end consumer. It involves various functions such as planning, sourcing, production, logistics, and customer service, all of which must work seamlessly to ensure efficiency and customer satisfaction. Understanding the key elements, types, and challenges in supply chain management is crucial for businesses to optimize their processes and stay competitive in today’s market. With the help of technology, supply chain managers can overcome these challenges and create a more efficient and effective supply chain.

Related Posts: